Training to Support Your Lean Journey

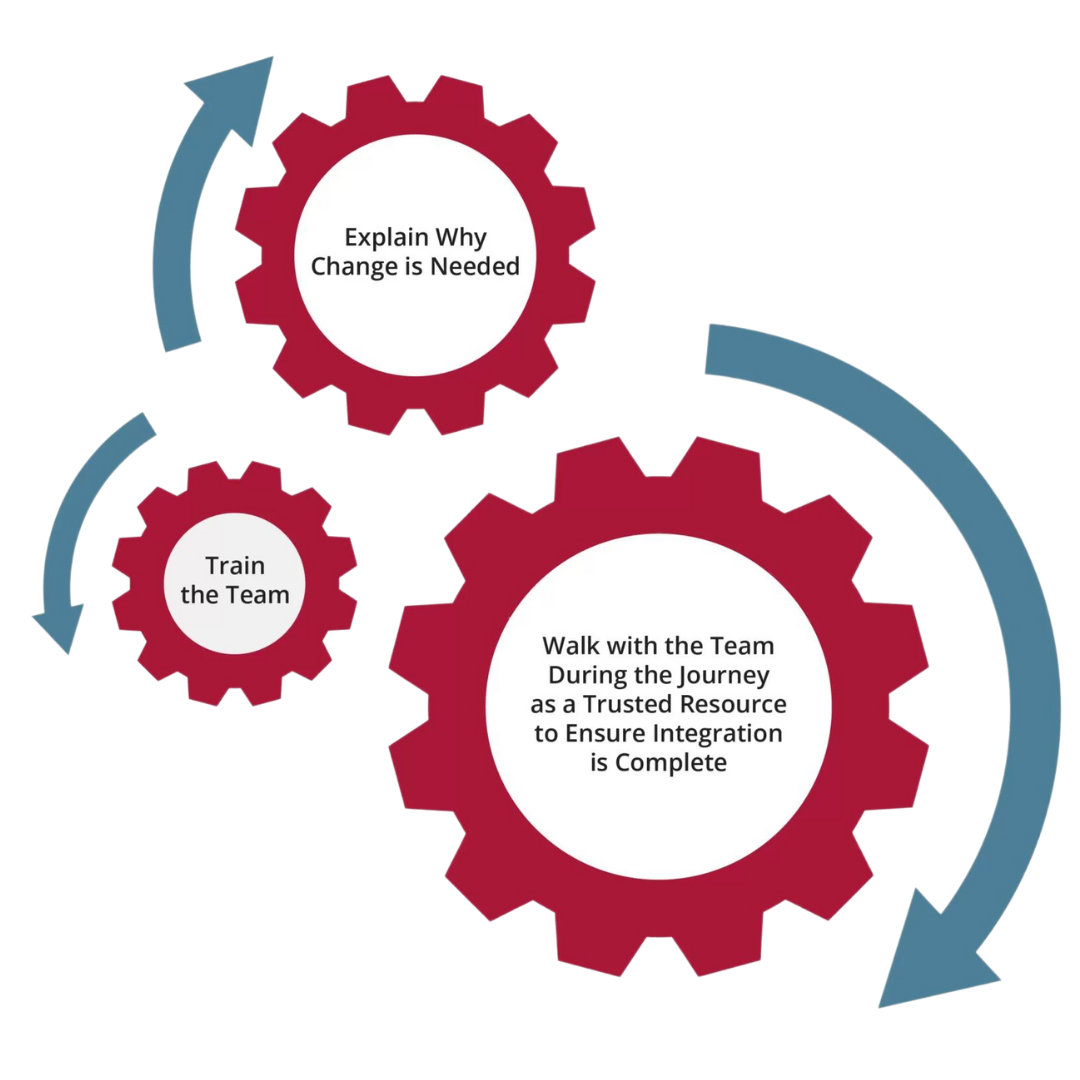

GKW Business Solutions Offers Training to Support the Lean Journey. Experience shows that there are 2 primary reasons that Lean Initiatives fail. Reasons are lack of training and the team does not understand why change is necessary and needed. GKW Business Solutions is a “Boots On The Ground” Trusted Resource to explain to the team on the floor why change is needed and will provide the training needed to support the lean transition.

Video Courses

Would you like to unlock your full potential? If so, check out our training catalogue.

With The GKW Online Learning courses, you can set yourself up to be the best you can be. With these courses, it will allow you to understand the topics, and implement them within your own facility.

Six Sigma Yellow Belt

The Six Sigma Yellow Belt certification provides individuals with a foundational understanding of process improvement methodologies and basic statistical analysis. Yellow Belts contribute to project teams, assist with data collection, and support process improvement initiatives within organizations.

Quick Changeover

Quick Changeover or SMED (Single-Minute Exchange of Die) is a lean manufacturing technique aimed at reducing equipment setup and changeover time. By streamlining and simplifying the process, SMED enables faster and more efficient equipment transitions, leading to increased productivity, reduced downtime, and improved overall operational efficiency.

Value Stream Mapping

Value stream mapping (VSM) is a lean management tool used to visually map and analyze the flow of materials, information, and activities within a process. It identifies value-added and non-value-added steps, enabling organizations to identify opportunities for process improvement, waste reduction, and increased efficiency.

Six Sigma Green Belt

The Six Sigma Green Belt certification equips individuals with in-depth knowledge of process improvement methodologies, statistical analysis, and project management. Green Belts lead projects, analyze data, implement improvements, and drive significant performance enhancements within organizations, working closely with Black Belt team members.

5S

5S is a lean methodology for workplace organization and efficiency. It stands for Sort, Set in Order, Shine, Standardize, and Sustain. By systematically organizing and maintaining a clean and efficient work environment, 5S enhances productivity, safety, and quality while reducing waste and inefficiencies.

Intro to Lean

Lean manufacturing is a systematic approach focused on eliminating waste, improving efficiency, and maximizing value in manufacturing processes. By optimizing flow, reducing defects, and involving all levels of the organization, lean manufacturing aims to achieve higher quality, shorter lead times, and increased customer satisfaction while minimizing costs and resources.

Easy As 1...2...3...

Here at GKW we want all parties to excel with our programs and to be successful with integrating lean within YOUR organization.

Ready to get started?

But have some questions?

Get in Touch.